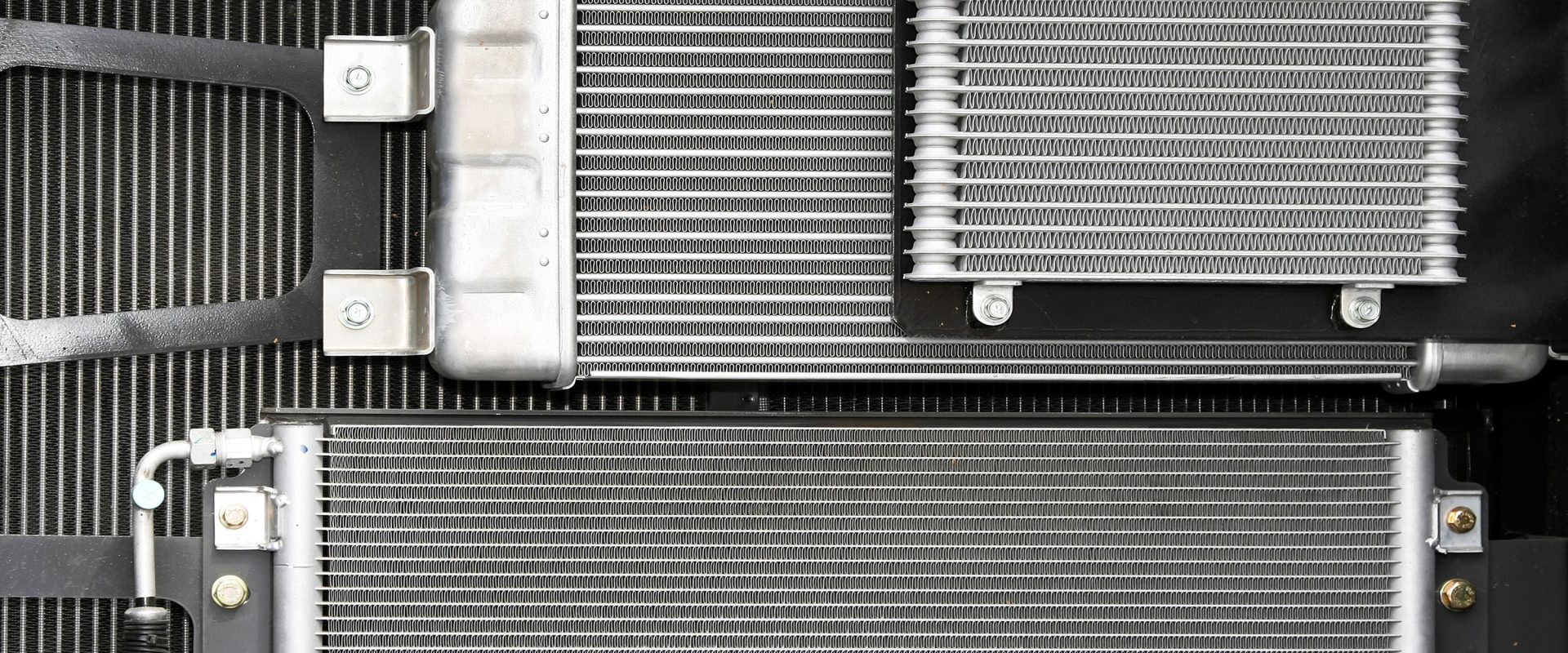

HVAC & Specialty Coatings

Since 2002, we have specialized in coatings for the HVAC market (Heating, Ventilation and Air Conditioning). Our focus is on hydrophilic and corrosion-protective coatings for evaporators. In addition, we offer soldering aids for aluminum soldering.

As a partner with many years of experience, we work with you to develop customized products for your application.

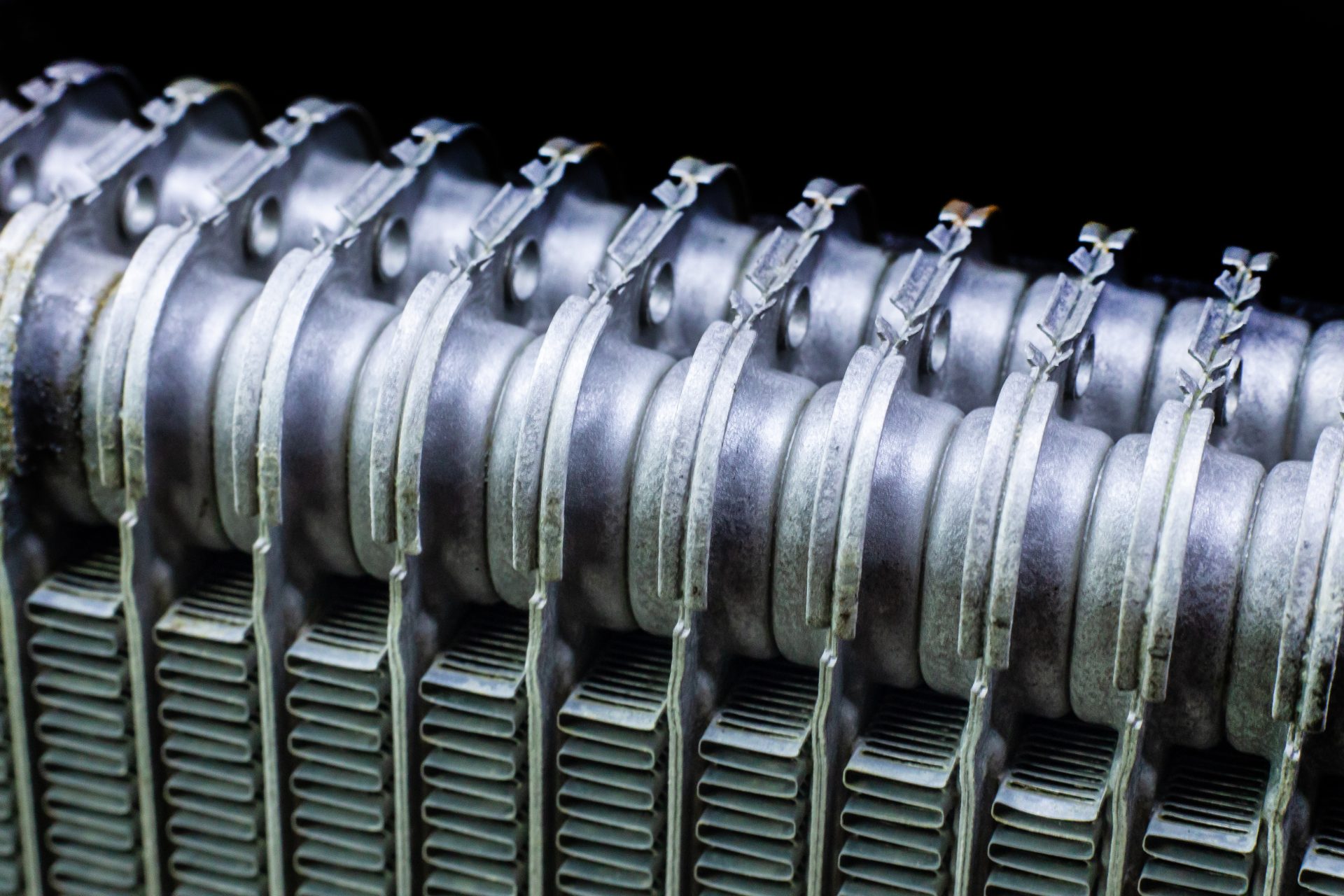

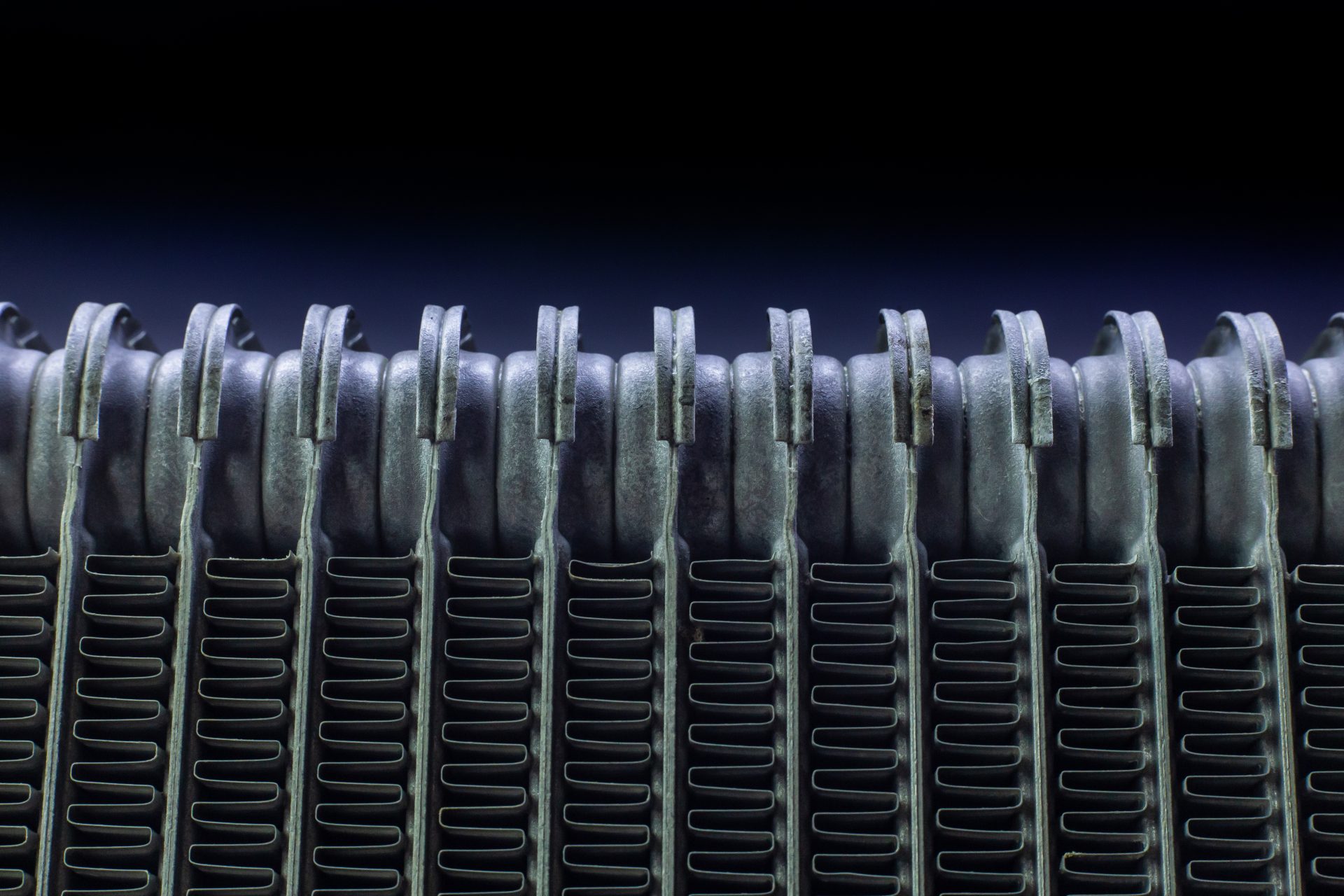

Hydrophilic

Hydrophilic coatings for evaporators, coolers, condensers optionally with coating protection agents (PT7)

- Layer thickness: 1-5 µm

- Flood or centrifuge

- Curing: 10 minutes 150 °C

- Odorless

- Contact angle: 20-50° (H2O)

- 240 h Condensation water test (CH)

- 240 h Salt spray test (NSS)

Hydrophilic +

Hydrophilic coatings + corrosion protection for evaporators, coolers, condensers optionally with coating protection agents(PT7)

- Layer thickness: 1-5 µm

- Flood or centrifuge

- Curing: 10 minutes 160°C

- Odorless

- Contact angle: 20-35° (H2O)

- Up to 1000 h condensation water test (CH)

- Up to 1000 h salt spray test (NSS)

Aluminum brazing

Binder for flux mixtures and pastes

- Residue free soldering

- Good flux adhesion

- Evaporation @300-350 °C

HVAC specialties

Are you looking for a solution to a specific problem? As a partner with many years of experience, we work with you to develop customized solutions for your application

- Please contact us

Exposed carbon specialties

Temperature-resistant coatings for visible carbon applications

- Layer thickness: 50-150 µm

- Single-component

- Thermal resistance up to 180 °C

- Very good grindability

- High solids content

- Glossy or matte available

- Good thermal, chemical and weathering resistance